Hoʻokuʻu ʻia i ka paipu palaki

-

Laina Hoʻokuʻu ʻia ʻo HDPE Pipe Nui

Hana & Pōmaikaʻi: ʻO ka Extruder ka JWS-H moʻo Kiʻekiʻe kiʻekiʻe, kiʻekiʻe kiʻekiʻe hoʻokahi screw extruder. ʻO ka hoʻolālā hoʻolālā pahu screw kūikawā e hōʻoia i ka hoʻoheheʻe ʻana o ka hoʻoheheʻe maikaʻi i nā wela haʻahaʻa haʻahaʻa. Hoʻolālā ʻia no ka extrusion paipu anana nui, ua hoʻolako ʻia ka mold distribution structure me kahi ʻōnaehana hoʻoluʻu i loko. Hoʻohui ʻia me kahi mea haʻahaʻa haʻahaʻa haʻahaʻa, hiki iā ia ke hana i nā paipu ultra-mānoanoa-pā, nui-diameter. ʻO Hydraulic wehe a pani ʻana i ʻelua mau pae pahu pahu, computerized centralized control and coordination of multiple crawler tractors, chipless cutter and all units, a high degree of automation. Hiki i ka tractor kaula uea koho ke hana i ka hana mua o ka paipu nui-caliber.

-

Laina Hoʻokuʻu ʻia ʻo Silicon Coating Pipe Extrusion

He polyethylene kiʻekiʻe ke kiʻekiʻe o ka papa o loko, ʻo ka ʻāpana o loko i hoʻohana i kahi mea hoʻonaninani haʻahaʻa haʻahaʻa silica gel solid lubricant. ʻO ia ka pale ʻana i ka corrosion, ka paia i loko maʻemaʻe, ka hoʻouna ʻana i ke kelepona puhi ahi kūpono, a me ke kumu kūʻai haʻahaʻa. E like me nā pono, ʻokoʻa nā ʻokoʻa a me nā kala o nā paipu liʻiliʻi e ka casing waho. Hoʻohana ʻia nā huahana i ka ʻōnaehana kelepona kelepona optical no ke ala kaʻa, kaʻaahi a pēlā aku.

-

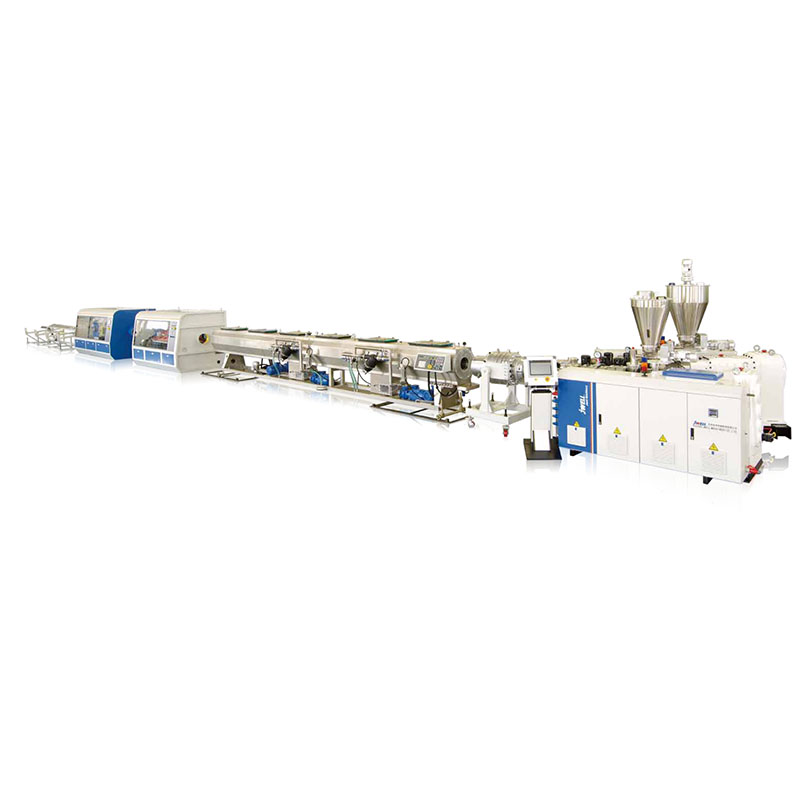

PVC-UH/UPVC/CPVC Pipe Extrusion Line

Hiki i nā ʻano kikoʻī a me nā hiʻohiʻona o PVC twin-screw extruder ke hana i nā paipu o nā anawaena like ʻole a me nā mānoanoa pā like ʻole. Hoʻolālā kūikawā i hoʻolālā ʻia me ka plasticization like a me ka puka kiʻekiʻe. ʻO nā mea hoʻoheheʻe extrusion i hana ʻia me ke kila kila kiʻekiʻe, ka hoʻoheheʻe ʻana i loko o ka chrome plating, ka mālama polishing, ka lole a me ka pale ʻana i ka corrosion; me ka lima kiʻekiʻe-wikiwiki nui i hoʻolaʻa ʻia, maikaʻi ka maikaʻi o ka ʻili o ka paipu. Hoʻohana ka mea ʻoki kūikawā no ka paipu PVC i kahi mea hoʻopili wili, ʻaʻole pono e hoʻololi i ka mea paʻa me nā anawaena paipu like ʻole. Me ka chamfering device, oki, chamfering, hoʻokahi-ʻanuʻu molding. Kākoʻo i ka mīkini bele pūnaewele koho.

-

ʻEkolu Layer PVC Pipe Co-extrusion laina

E hoʻohana i ʻelua a ʻoi aku paha SJZ series conical twin screw extruder no ka hoʻokō ʻana i ka paipu PVC ʻekolu-papa. ʻO ka papa sandwich o ka paipu he kiʻekiʻe-calcium PVC a i ʻole PVC foam raw material.

-

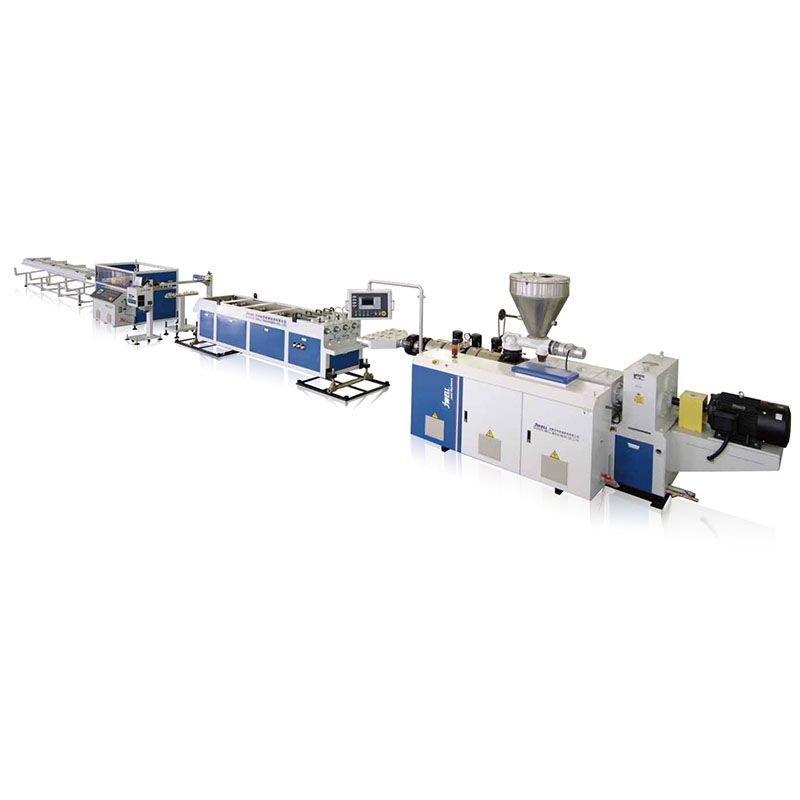

ʻO ka laina hoʻokuʻu ʻana i ka paipu PVC pālua

E like me nā koi like ʻole o ke anawaena paipu a me ka hoʻopuka ʻana, aia ʻelua ʻano o SJZ80 a me SJZ65 kūikawā twin-screw extruders koho; ka lua paipu make like puunaue i ka mea, a me ka paipu extrusion wikiwiki ua plasticized. Hiki ke hoʻokaʻawale kaʻawale ka pahu hoʻoluʻu lua-vacuum kiʻekiʻe, a maʻalahi ka hana hoʻoponopono i ka hana hana. Mīkini ʻoki lepo ʻole, mana kūʻokoʻa kūʻokoʻa pālua, wikiwiki wikiwiki, lōʻihi ʻoki pololei. Hoʻopau nā puʻupuʻu pneumatically rotating i ka pono e hoʻololi i nā clamps. Me ka chamfering mea koho.

-

PVC Eha Pipe Extrusion Line

Nā hiʻohiʻona hana: ʻO ke ʻano hou loa o ʻehā PVC uila busing laina hana hana i kahi twin-screw extruder me ka kiʻekiʻe kiʻekiʻe a me ka hana plasticization maikaʻi, a ua hoʻolako ʻia me kahi mold i hoʻolālā ʻia no ka hoʻolālā ala kahe. ʻEhā mau paipu i hoʻokuʻu like a me ka wikiwiki o ka extrusion. Hiki ke ho'omalu 'ia a ho'oponopono 'ia nā pahu ho'olu'u 'ehā me ka ho'opilikia 'ole i kekahi i kekahi ma ke ka'ina hana.

-

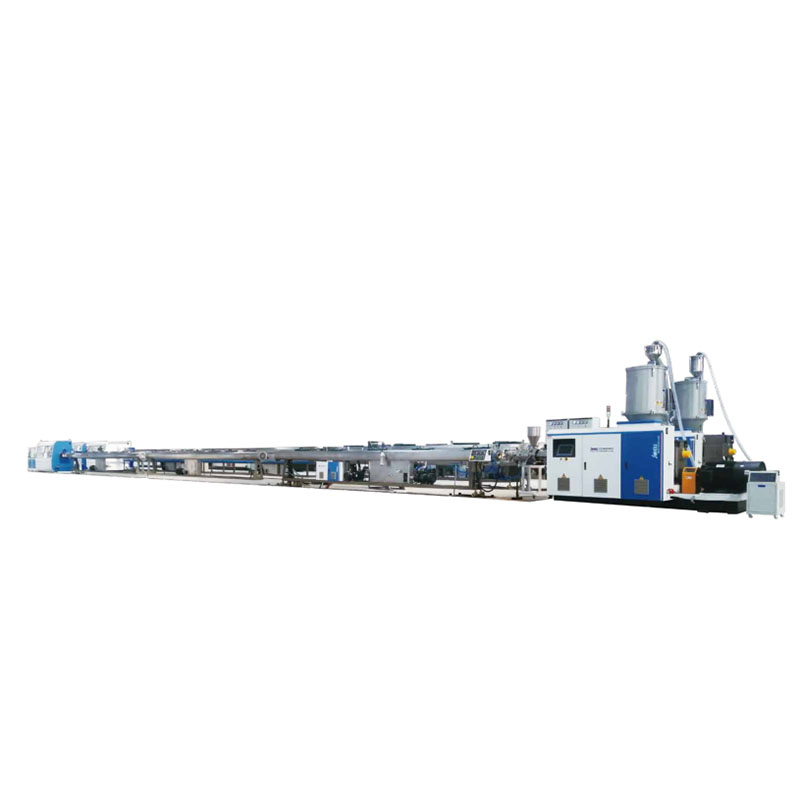

High-speed Energy-saving HDPE Pipe Extrusion Line

ʻO ka paipu HDPE kahi ʻano paipu plastik maʻalahi i hoʻohana ʻia no ka hoʻololi ʻana i ka wai a me ke kinoea a hoʻohana pinepine ʻia e hoʻololi i nā paipu palaki kahiko a i ʻole nā paipu kila. Hana ʻia mai ka thermoplastic HDPE (high-density polyethylene), ʻo kona kiʻekiʻe kiʻekiʻe o ka impermeability a me ka paʻa molekala ikaika e kūpono ia no nā paipu kiʻekiʻe. Hoʻohana ʻia ka paipu HDPE ma ka honua holoʻokoʻa no nā noi e like me ka nui o ka wai, ka ʻea kinoea, ka ʻili wai, nā laina hoʻoili slurry, ka hoʻoheheʻe ʻana i nā kuaʻāina, nā laina lako ahi, nā uila a me nā mea kamaʻilio, a me ka wai ʻino a me nā paipu wai.

-

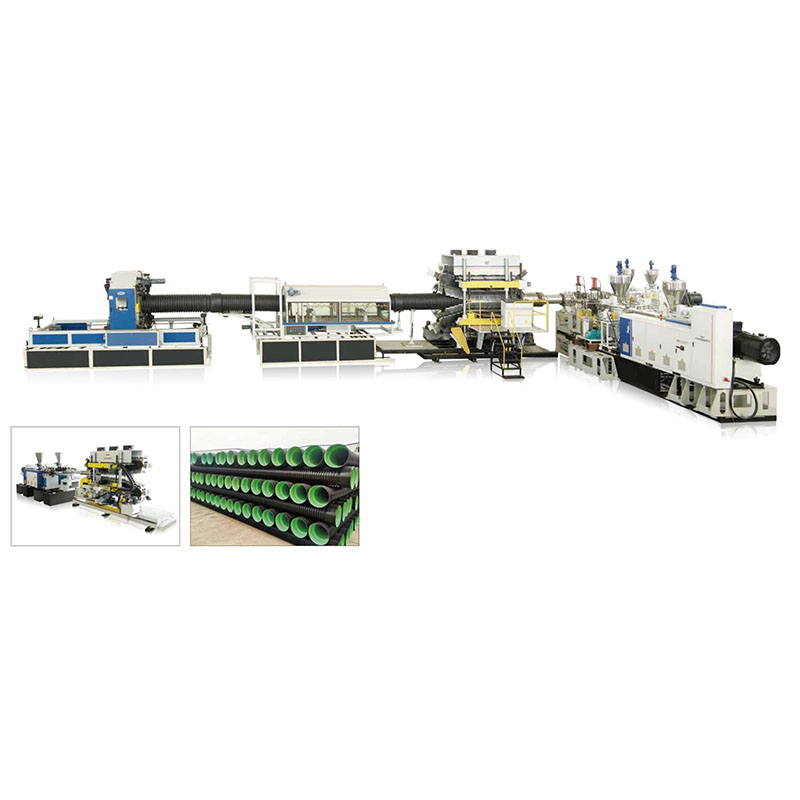

High-speed Single Screw HDPE/PP DWC Pipe Extrusion Line

ʻO ka laina paipu corrugated ʻo ia ka hanauna 3 o ka huahana i hoʻomaikaʻi ʻia o Suzhou Jwell. Hoʻonui nui ʻia ka puka o ka extruder a me ka wikiwiki o ka paipu e 20-40% i hoʻohālikelike ʻia me ka huahana mua. Hiki ke hoʻokō ʻia ka bele pūnaewele e hōʻoia i ka hana o nā huahana paipu corrugated i hana ʻia. Hoʻokomo i ka ʻōnaehana HMI Siemens.

-

ʻO ka laina hoʻoheheʻe ʻana i ka paipu DWC

Ua hoʻokomo ʻo Suzhou Jwell i ka ʻenehana holomua ʻEulopa a ua kūkulu hou ʻia ʻo parallel-parallel twin screw extruder HDPE/PP DWC pipe line.

-

ʻO ka laina hoʻoheheʻe nui HDPE Pipe Co-extrusion

E like me nā pono kūikawā o nā mea hoʻohana, hiki iā mākou ke hāʻawi i ka laina paipu pā paʻa paʻa 2-layer / 3-layer / 5-layer. Hiki ke hoʻonohonoho like ʻia nā extruders lehulehu, a hiki ke koho ʻia nā ʻōnaehana mana kaumaha mau mika. hiki ke hoʻomalu i ke kikowaena i kahi PLC nui e hoʻokō i ka extrusion pololei a me ka quantitative o kēlā me kēia extruder. E like me ka multi-layer spiral mold i hoʻolālā ʻia me nā ʻāpana like ʻole a me nā lakio mānoanoa, ka hāʻawi ʻana i ka kahe o ka mold cavity.He kūpono nā kahawai e hōʻoia i ka ʻokoʻa o ka mānoanoa o ka paipu a ʻoi aku ka maikaʻi o ka hopena plasticization o kēlā me kēia papa.

-

ʻO ka wai hoʻoluʻu HDPE/PP/PVC DWC Pipe Extrusion Line

Hoʻohana ʻia ʻo HDPE Corrugated Pipes i nā papahana sewerage i ka lawe ʻana i nā ʻōpala ʻoihana i loko o ka wai ʻino a me ka lawe ʻana i nā wai wai.

-

HDPE Heat Insulation Pipe Extrusion Line

Ua kapa ʻia ʻo PE paipu insulation pipe PE outer protection pipe, jacket pipe, sleeve pipe. Hana ʻia ka paipu insulation polyurethane i kanu ʻia me ka paipu insulation HDPE ma ke ʻano he pale pale o waho, hoʻohana ʻia ka polyurethane rigid foam i hoʻopiha ʻia ma ke ʻano he mea hoʻoheheʻe, a ʻo ka ʻaoʻao o loko he paipu kila. Polyure-thane pololei kanu insulation paipu i maikai mechanical waiwai a me ka thermal insulation hana. Ma lalo o nā kūlana maʻamau, hiki iā ia ke kū i ke kiʻekiʻe kiʻekiʻe o 120-180 ° C, a he kūpono ia no nā ʻano wai anuanu a me ka wai wela kiʻekiʻe a me ka haʻahaʻa haʻahaʻa o ka pipeline insulation projects.