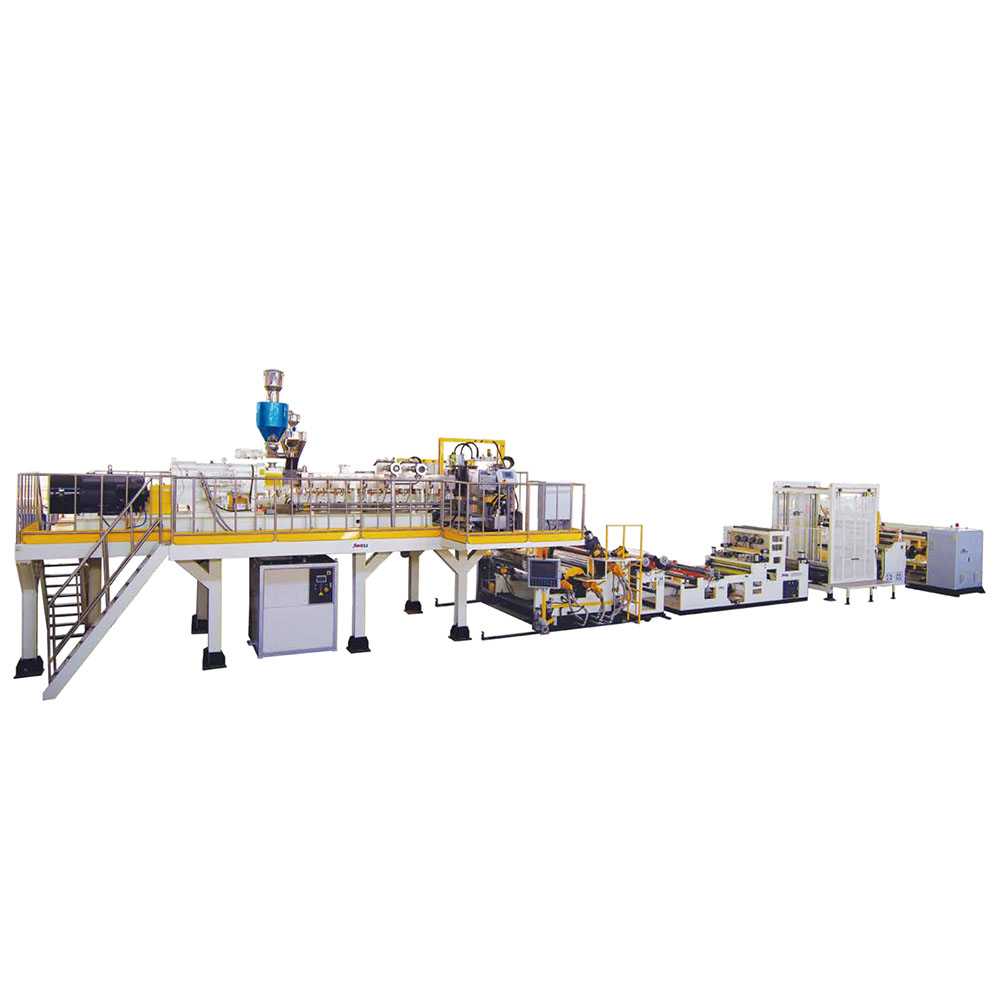

PET/PLA Sheet Extrusion Line

ʻĀpana ʻenehana nui

| Hoʻohālike | Hoʻohālike extruder | Mānoanoa huahana (mm) | Ka mana kaʻa nui (kw) | Ka nui o ka extrusion (kg/h) |

| ʻĀpana lehulehu | JWE75/40+JWE52/40-1000 | 0.15-1.5 | 132/15 | 500-600 |

| Papa hoʻokahi | JWE75/40-1000 | 0.15-1.5 | 160 | 450-550 |

| Kiʻekiʻe-efficient | JWE95/44+JWE65/44-1500 | 0.15-1.5 | 250/75 | 1000-1200 |

| Kiʻekiʻe-efficient | JWE110+JWE65-1500 | 0.15-1.5 | 355/75 | 1000-1500 |

Nānā: Hiki ke hoʻololi i nā kikoʻī me ka ʻole o ka hoʻolaha mua.

ʻĀpana ʻenehana nui

| Hoʻohālike | ʻĀpana lehulehu | Papa hoʻokahi | Kiʻekiʻe-efficient |

| Hōʻike kikoʻī Extruder | JW120/65-1000 | JW120-1000 | JW150-1500 |

| Ka mānoanoa o ka huahana | 0.20-1.5mm | 0.2-1.5mm | 0.2-1.5mm |

| Mana kaʻa nui | 132kw/45kw | 132kw | 200kw |

| ʻO ka mana extrusion nui | 600-700kg/h | 550-650kg/h | 800-1000kg/h |

Nānā: Hiki ke hoʻololi i nā kikoʻī me ka ʻole o ka hoʻolaha mua.

Pepa PLA

ʻO PLA kahi ʻano laina ʻano Aliphatic Polyesters. Hiki ke hoʻohana ʻia ʻo PLA i loko o ka ʻeke paʻa o nā huaʻai, nā mea kanu, nā hua manu, nā meaʻai i kuke ʻia a me nā meaʻai ʻai ʻai, hiki ke hoʻohana ʻia no ka hoʻopili ʻana i ka sanwiti, biscuit a me nā ʻāpana ʻē aʻe e like me ka pua hou.

Hōʻike huahana

Hiki ke hoʻoheheʻe ʻia ka polylactic acid (PLA) i carbon dioxide a me ka wai ma lalo o nā kūlana kūlohelohe ma hope o ka hoʻolei ʻia ʻana. Loaʻa iā ia ke kūpaʻa wai maikaʻi, nā waiwai mechanical, biocompatibility, hiki ke hoʻopili ʻia e nā meaola, a ʻaʻohe haumia i ke kaiapuni. I ka manawa like, loaʻa iā PLA nā waiwai mechanical maikaʻi. Loaʻa iā ia ka ikaika hopena kiʻekiʻe, ka loli maikaʻi a me ke kūpaʻa wela, ka plasticity, processability, ʻaʻohe discoloration, permeability maikaʻi i ka oxygen a me ka wai wai, a me ka transparency maikaʻi, anti-mildew, antibacterial, ke ola lawelawe ʻo 2 ~ 3 mau makahiki.

ʻO ka papa kuhikuhi hana koʻikoʻi o nā mea hoʻopihapiha ka ea permeability, a hiki ke hoʻoholo ʻia ke kahua noi o kēia mea i loko o ka ʻeke e like me ka ʻokoʻa o ka ea permeability o nā mea. Pono kekahi mau mea hoʻopili i ka oxygen permeability e hoʻolako i ka oxygen i ka huahana; ʻO kekahi mau mea hoʻopihapiha e koi aku i kahi pale i ka oxygen ma ke ʻano o nā mea, e like me ka hoʻopili ʻana i ka mea inu, e koi ana i nā mea hiki ke pale aku i ka oxygen mai ke komo ʻana i ka pōʻai e pale ai i ka mold. hopena o ka ulu. Loaʻa iā PLA ka pale kinoea, ka pale wai, ka ʻike a me ka paʻi maikaʻi.

ʻO ka PLA maikaʻi ka ʻike a me ka ʻōlinolino, a ua hoʻohālikelike ʻia kāna hana maikaʻi me cellophane a me PET, ʻaʻole i loaʻa i nā plastic degradable ʻē aʻe. ʻO ka māmā a me ka nani o PLA he 2 ~ 3 mau manawa o ka kiʻi PP maʻamau a me 10 mau manawa o LDPE. ʻO kona ʻike kiʻekiʻe e hoʻohana i ka PLA i mea nani. No ka laʻana, hoʻohana ʻia ia no ka hoʻopaʻa lole. I kēia manawa, hoʻohana ka nui o nā ʻeke lole ma ka mākeke i nā kiʻi ʻoniʻoni PLA.

ʻO ka hiʻohiʻona a me ka hana ʻana o kēia kiʻi paʻi e like me nā kiʻi ʻoniʻoni lole lole kahiko, me ka ʻike kiʻekiʻe, ka paʻa kink maikaʻi loa, ka paʻi ʻana a me ka ikaika, a me nā waiwai pale maikaʻi loa, hiki ke mālama maikaʻi i ka ʻono o ka candy. Ke hoʻohana nei kekahi hui Kepani i ka PLA brand "racea" o ka American Cakir Dow Polymer Company ma ke ʻano he mea hoʻopili no nā huahana hou, a ʻike maopopo loa ka ʻōpala i ka helehelena. Ua hoʻomohala ʻo Toray Industries i nā kiʻiʻoniʻoni a me nā ʻāpana hana PLA me ka hoʻohana ʻana i kāna ʻenehana nano-alloy proprietary. Loaʻa i kēia kiʻiʻoniʻoni ka wela like a me ka pale ʻana i ka hopena e like me nā kiʻiʻoniʻoni e pili ana i ka petroleum, akā loaʻa nō hoʻi ka elasticity maikaʻi loa a me ka ʻike.

Hiki ke hana ʻia ʻo PLA i mau huahana kiʻiʻoniʻoni me ka ʻike kiʻekiʻe, nā waiwai pale maikaʻi, ka hana maikaʻi loa a me nā waiwai mechanical, a hiki ke hoʻohana ʻia no ka hoʻopili maʻalahi o nā huaʻai a me nā mea kanu. Hiki iā ia ke hana i kahi mālama mālama kūpono no nā huaʻai a me nā mea kanu, mālama i nā hana ola o nā huaʻai a me nā mea kanu, hoʻopaneʻe i ka ʻelemakule, a mālama i ke kala, ʻala, ʻono a me ke ʻano o nā huaʻai a me nā mea kanu. Eia nō naʻe, ke hoʻohana ʻia i nā mea hoʻopihapiha meaʻai maoli, pono kekahi mau hoʻololi e hoʻololi i nā hiʻohiʻona o ka meaʻai ponoʻī, i mea e loaʻa ai kahi hopena ʻoi aku ka maikaʻi.

Hiki i ka PLA ke hana i kahi kaiapuni palupalu palupalu ma ka ʻili o ka huahana, nona ke kumu o ka antibacterial a me ka antifungal. Inā hoʻohana ʻia nā mea antibacterial ʻē aʻe, hiki ke hoʻokō ʻia ka nui o ka antibacterial ma mua o 90%, hiki ke hoʻohana ʻia no ka hoʻopili antibacterial o nā huahana.

Ke hoʻohālikelike ʻia me LDPE film, PLA film a me PLA/REO/TiO2 film, ʻoi aku ka kiʻekiʻe o ka wai permeability o PLA/REO/Ag composite film ma mua o nā kiʻiʻoniʻoni ʻē aʻe. Ua hoʻoholo ʻia mai kēia hiki ke pale pono i ka hoʻokumu ʻana o ka wai condensed a hoʻokō i ka hopena o ke kāohi ʻana i ka ulu ʻana o nā microorganisms; i ka manawa like, loaʻa iā ia kahi hopena bacteriostatic maikaʻi loa.

PET/PLA kaiapuni pepa extrusion laina: JWELL hoʻomohala i ka māhoe māhoe extrusion laina no ka PET/PLA pepa, keia laina i lako me ka degassing nenoaiu, a me ka pono ole maloo a crystallizing wae. Loaʻa i ka laina extrusion nā waiwai o ka comsuption ikehu haʻahaʻa, ka hana maʻalahi a me ka mālama maʻalahi. Hiki i ka ʻāpana ʻāpana ʻāpana ke hōʻemi i ka nalowale o ka viscosity o ka resin PET/PLA, ʻo ka ʻōleʻa kalameka symmetrical a me ka lahilahi-wall e hoʻokiʻekiʻe i ka hopena ʻoluʻolu a hoʻomaikaʻi i ka hana a me ka maikaʻi o ka pepa. Hiki i nā ʻāpana dosing feeder ke hoʻomalu i ka pākēneka o nā mea puʻupaʻa, mea hana hou a me master batch pololei, hoʻohana nui ʻia ka pepa no ka ʻoihana hoʻopihapiha thermoforming.